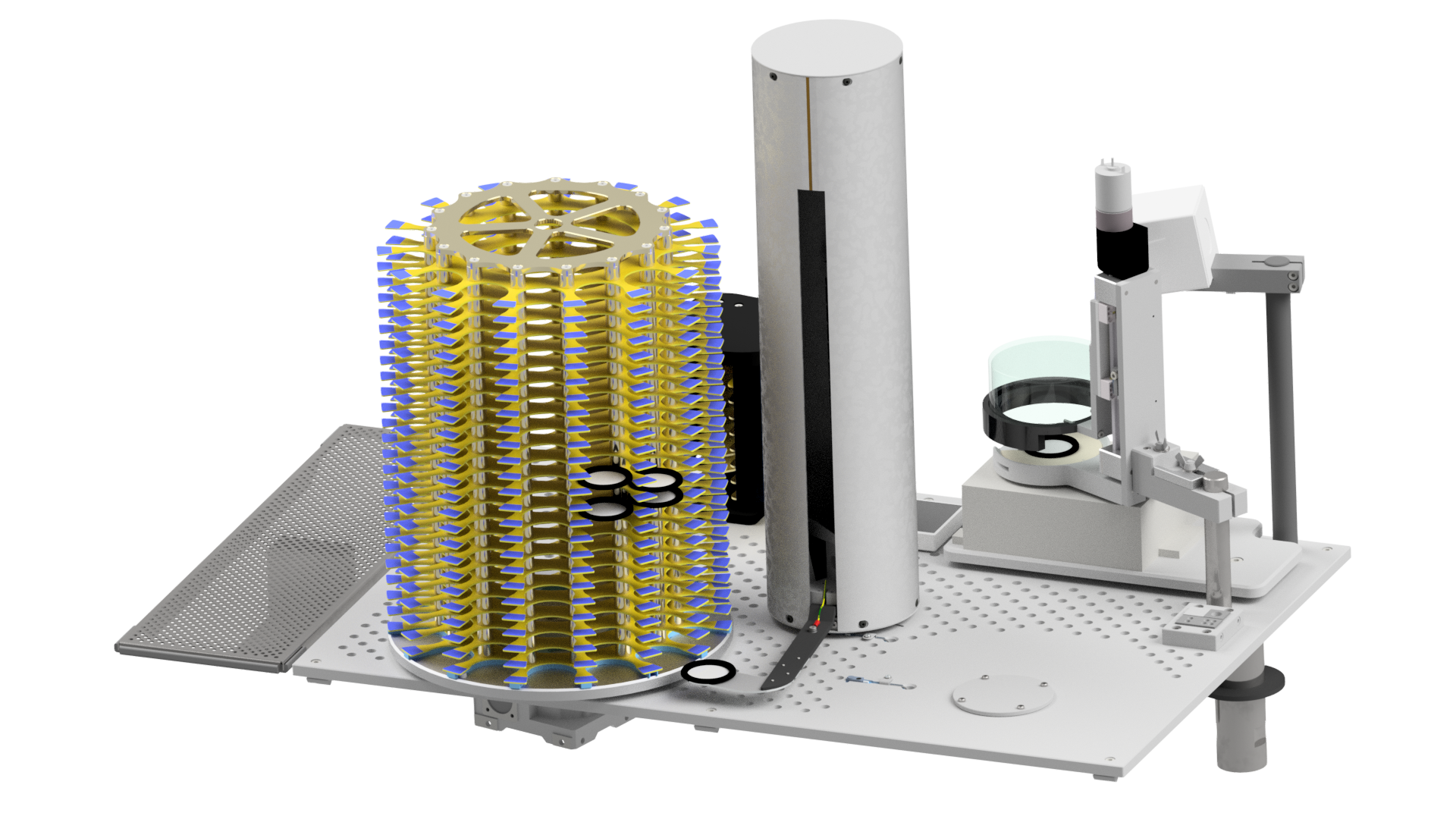

System configuration

The automatic weighing system AWS-1RE consists of the following principal components:

- Dustproof weighing chamber with:

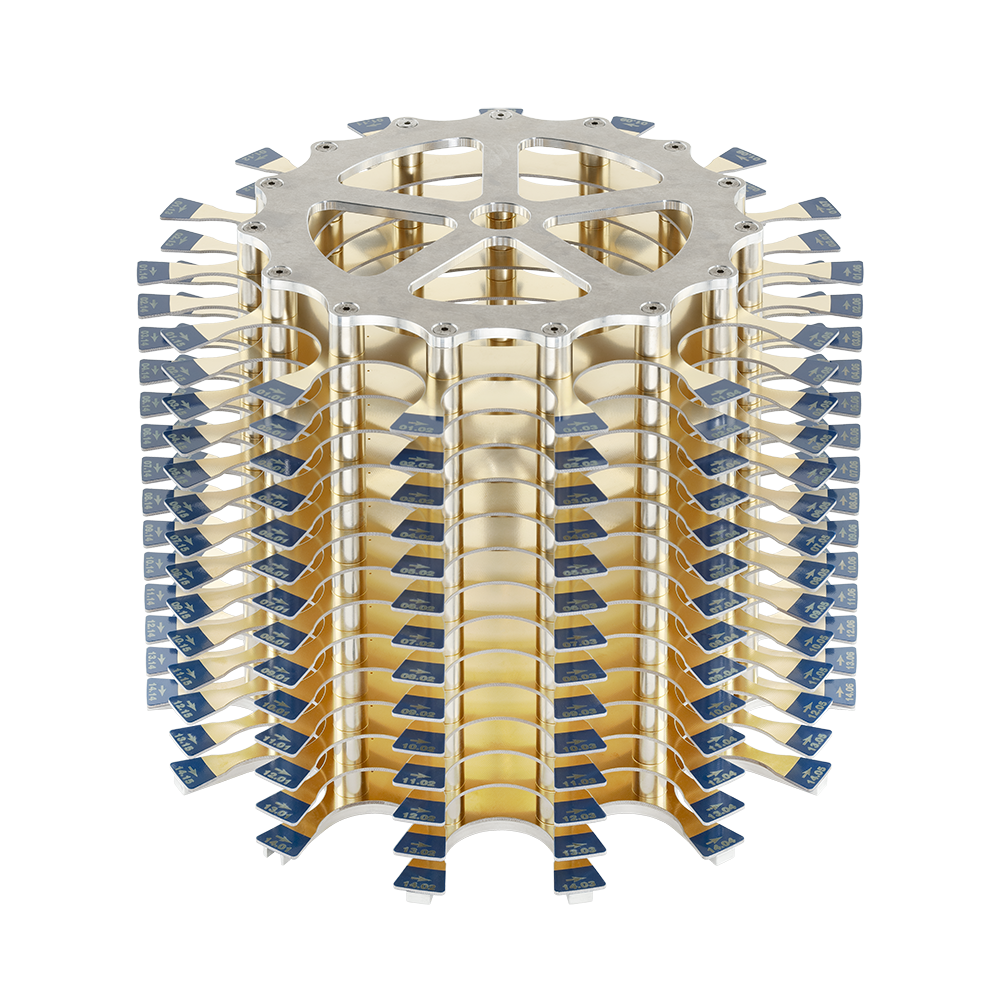

- Filter disc magazines for holding filters before and after weighing

- Patented RFID filter trays with data storage for contactless encoding and identification of the filters

- Microbalance with draft shield

- Ultra-microbalance (optional, most existing balances can be integrated after modification)

- Fan filter unit (FFU) to protect the weighing chamber against contamination

- Climate control unit

- Ionization system for neutralizing the filters (“eliminating” static electricity)

- PC with system software AWS Control (featuring custom encoding function)

- Power supply cabinet underneath the weighing chamber

Operating principle and weighing process

Before the first weighing operation is performed, the unsampled filters are manually placed into filter trays and inserted into the filter magazines of the AWS-1RE. The system automatically recognizes each individual filter by contactless RFID technology. During the weighing process, the system stores environmental and ancillary data on the filter tray’s chip and also in the database of a connected PC.

First, the filters are preconditioned for the desired time, according to chosen parameters. The next step is the first weighing series, which consists of weighing the unsampled filters, usually in two weighing passes. The ionization system located near the balance “eliminates” the static electricity of the filters, and thus enhances weighing accuracy. Once the unsampled filters have been weighed, they are taken out of the weighing chamber and made ready for sampling.

After sampling, the filters are returned to the filter trays, introduced into the weighing chamber and conditioned again. The second weighing series (weighing the sampled filters) follows, once again with two or possibly three weighing passes. Previously coded filters can be identified by the RFID station, which allows the sampled reading to be compared directly with the preceding unsampled reading. Both before and during the weighing series, verification weighing operations can be performed with reference filters in order to monitor the climatic conditions inside the weighing chamber. During the weighing operation, all the data (weighed values, mean values, weight difference between unsampled and sampled filters, and ancillary data, such as temperature and relative humidity) are saved in the database on the system PC.

The saved data can subsequently be exported for analysis and processing. The concentration of particulate matter is calculated from the weight difference between the sampled and unsampled filters, giving consideration to the air flow rate.

Benefits

Compared with manual lab weighing, the AWS-1RE offers the benefits of an automatic filter handling in a contamination-free weighing chamber, designed specifically for weighing filters. The connected system PC facilitates reliable recording of the weighing results, comparisons between individual weighing passes, and continuous monitoring of the climatic conditions. The system rules out inaccurate records and delivers reliable, precise results by manual weighing. An integrated filter magazine can accommodate a large number of filters in a protected environment. The climate control unit maintains the necessary climatic conditions throughout the entire process.

Detailed information is contained in the data sheet “Automatic Weighing System AWS-1RE”.

The information on this website represents the state of knowledge at the time of writing. Technical specifications are subject to modifications. Comde-Derenda GmbH accepts no liability whatsoever for the content provided or for damages resulting from the use of its products.